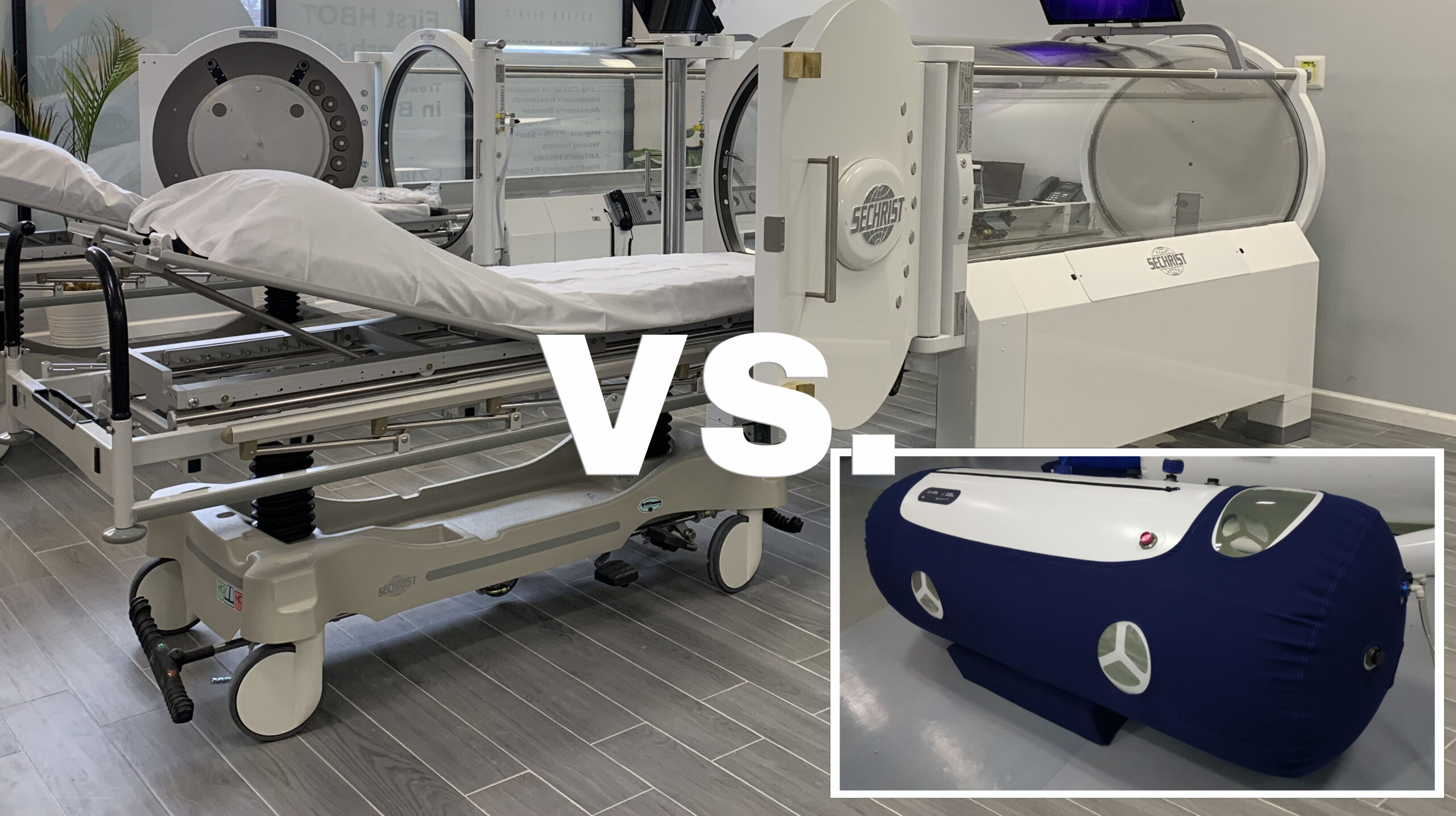

Hyperbaric oxygen therapy (HBOT) is a medical treatment for many conditions that uses increased atmospheric pressure and concentrated oxygen to heal and treat. This therapy is delivered through two main chamber types: hard shell (rigid) and soft shell (flexible) hyperbaric chambers. As a medical professional, facility administrator, or patient considering HBOT treatment options, it’s essential to understand the differences between these systems.

What is Hyperbaric Oxygen Therapy?

Hyperbaric oxygen therapy involves breathing pure oxygen in a pressurized environment, usually above sea level atmospheric pressure. The combination of increased pressure and concentrated oxygen dissolves oxygen in blood plasma, oxygenates tissue, and triggers various physiological responses that support healing. It’s used to treat conditions ranging from decompression sickness and carbon monoxide poisoning to diabetic wounds and radiation injuries.

Hard Shell Hyperbaric Chambers

Hardshell hyperbaric or rigid chambers are the traditional standard for clinical HBOT delivery. These chambers are made of steel, aluminum, or composite materials and are a solid, permanent structure that can withstand significant pressure differentials.

Technical Specifications and Features

Hard shell chambers operate at 1.5 to 3.0 atmospheres absolute (ATA); some specialized units can go even higher. Their rigid construction allows precise pressure control and maintains structural integrity in extreme conditions. They have multiple viewports, advanced life support systems, and sophisticated monitoring equipment.

Oxygen is delivered in hard shell chambers through various methods, including built-in breathing systems, oxygen masks, and hoods. Depending on the treatment protocol and safety considerations, the chamber can be pressurized with air, and the patient breathes pure oxygen through delivery devices, or the entire chamber can be flooded with oxygen.

Clinical Applications and Benefits

Hard shell chambers are best for acute, life-threatening conditions that require immediate high-pressure intervention. They can reach higher pressures, making them essential for decompression sickness, arterial gas embolism, and severe carbon monoxide poisoning. The robust construction and advanced monitoring systems provide extra safety margins for critically ill patients.

Hard shell chambers can treat multiple patients at once in larger multiplace units. This increases treatment efficiency and allows medical personnel to stay inside the chamber during treatment and provide direct patient care and monitoring.

Limitations and Considerations

The main disadvantages of hard shell chambers are the high initial cost, permanent installation requirements, and ongoing maintenance requirements. These systems require dedicated facilities with specialized infrastructure, pressure-rated plumbing, electrical systems, and ventilation. The operational costs are high due to energy consumption, maintenance, and the need for trained technical personnel.

Soft Shell Hyperbaric Chambers

Softshell hyperbaric chambers made of flexible materials like reinforced vinyl or polyurethane offer an alternative to HBOT delivery. These chambers have a different design philosophy, portability, cost-effectiveness, and ease of use.

Design and Operational Features

Soft shell chambers operate at lower pressures, usually 1.3 to 1.5 ATA, due to material constraints and safety considerations. The flexible construction requires a continuous air supply to maintain pressurization, and patients breathe concentrated oxygen through masks or nasal cannulas while the chamber atmosphere is pressurized.

Soft shell chambers are highly portable, as they can be deflated for storage or transport and do not require permanent installation. Setup is generally straightforward; you just need electrical power and enough space to deploy.

Clinical Effectiveness and Applications

Hyperbaric oxygen therapy is effective against non-healing wounds and bacterial, viral, and fungal infections. Research shows that oxygen at 1.5 ATA or higher has bacteriostatic properties, inhibiting bacterial and fungal growth. Hard-shell hyperbaric oxygen therapy typically operates above 2.0 ATA, suppressing bacterial growth.

Conversely, soft-sided chambers, operating at an average of 1.3 ATA, cannot inhibit bacterial growth and may even encourage the proliferation of bacteria, mold, and fungus. This exposure can worsen existing conditions or lead to new medical complications.

Mild/soft chambers are not recognized as medical devices and are only approved for treating altitude sickness. They do not offer the same benefits as hard-shell chambers in hyperbaric oxygen therapy. Medical-grade hard-shell chambers are used in case studies to demonstrate the therapy’s advantages.

Mild/soft chambers only reach 1.3 ATA, insufficient to deliver a therapeutic dose of oxygen—the primary benefit of hyperbaric therapy. They increase oxygen intake by only 6.3% above the 21% found in normal air, offering minimal additional benefits, and are comparable to breathing regular air.

To illustrate the difference in oxygen content, consider arterial blood gas levels:

- Normal air conditions and pressure: Blood oxygen levels are approximately 157 mmHg.

- Soft chamber (1.3 ATA with 24% oxygen): Levels rise to 230 mmHg.

- Oxygen mask in ambulance (55% oxygen at normal pressure): Levels reach 418 mmHg.

- Hard-shell chambers (2.4 ATA with 100% oxygen): Arterial oxygen levels can surge to 1,824 mmHg, demonstrating a significant difference.

Economic and Practical Advantages

The cost difference between soft and hard shell chambers is substantial; soft shell units are a fraction of the cost of rigid ones. This has democratized access to hyperbaric therapy, allowing smaller clinics, wellness centers, and even individuals to offer HBOT as a treatment or “wellness” option.

The simplified operational requirements of soft shell chambers reduce the need for extensive technical training and specialized facility modifications. This has contributed to the proliferation of HBOT services in non-traditional medical settings.

Safety Considerations and Regulations

Safety protocols differ greatly between chamber types due to their operational characteristics and pressure capabilities. Hard shell chambers require complete safety systems, emergency decompression procedures, fire suppression systems, and redundant life support mechanisms. The higher pressures require strict adherence to established medical protocols and trained operator supervision.

Clinical Evidence and Outcomes

The clinical evidence for hyperbaric oxygen therapy varies greatly depending on the condition treated, the pressure used, and the treatment protocol. Hardshell chambers have extensive research support for established indications like decompression sickness, non-healing wounds, and radiation injuries. The higher pressures achievable in rigid chambers are often considered necessary for maximum therapeutic benefit.

Materials in HBOT Chambers and Why Hard Shell Chambers Are More Reliable

The construction materials used in hyperbaric oxygen therapy (HBOT) chambers fundamentally determine their performance capabilities, safety profiles, and reliability. Understanding the material differences between hard and soft shell chambers reveals why hard shell systems are more reliable for clinical applications.

Hard Shell Chamber Materials

Hard shell hyperbaric chambers utilize robust, rigid construction materials to withstand extreme pressure differentials and provide long-term durability. The primary materials for viewing surfaces include medical-grade stainless steel, aluminum, and acrylic. These materials are selected for their high resistance to pressure, ease of maintenance, and long lifespan.

Stainless Steel Construction

Medical-grade stainless steel is the primary structural material for most hard-shell chambers. This material offers exceptional strength-to-weight ratios and corrosion resistance, making it ideal for hyperbaric therapy’s pressurized, oxygen-rich environment. Stainless steel maintains its structural integrity under repeated pressure cycles, resisting fatigue and deformation that could compromise chamber safety.

Aluminum Alternatives

Some manufacturers utilize aluminum construction for its lighter weight while maintaining pressure resistance. Aluminum chambers offer similar durability to steel while reducing overall system weight, though they may require specialized coatings to prevent oxidation in oxygen-enriched environments.

Composite Materials

Advanced composite chambers use aerospace-grade materials, including carbon fiber and reinforced polymers, providing lightweight yet durable construction. These materials combine the strength characteristics of metals with reduced weight and enhanced portability, which is particularly beneficial for mobile clinical environments.

Viewing Components

Acrylic viewing surfaces allow visual monitoring while maintaining pressure integrity. These transparent components undergo rigorous testing to withstand the exact pressure differentials as the primary chamber structure.

Soft Shell Chamber Materials

Soft shell chambers employ flexible materials that create a different structural approach to pressure containment. These chambers are constructed from flexible materials such as nylon, polyurethane, and specialized polymer blends.

Why Hard Shell Chambers Are More Reliable

Multiple material and design advantages, which become critical in clinical applications, contribute to hard shell chambers’ superior reliability.

Structural Integrity and Pressure Capabilities

Hard shell materials provide inherent structural stability that doesn’t depend on continuous pressurization for shape maintenance. Hard shell chambers can achieve significantly higher pressures than their soft shell counterparts, with operational ranges typically extending to 3.0 ATA or higher, compared to most soft shell systems’ 1.3-1.5 ATA limitation*.

*Let’s Do the Math—A portable soft shell chamber may be pressurized to 1.3 ATA, or 988 mmHg pressure. If you breathe the air inside the chamber, you’re breathing 160 mmHg oxygen x 1.3 ATA = 208 mmHg. This number is equivalent to breathing 27% oxygen from a mask sitting in your home at sea level. So, you don’t really need a chamber for this amount of oxygen.

The rigid construction of a hard shell chamber eliminates pressure-related deformation, ensuring consistent internal dimensions and reliable pressure delivery throughout treatment sessions. This structural stability becomes essential when treating conditions requiring precise pressure protocols or accommodating life support equipment.

Material Fatigue Resistance

Hard shell chambers are generally better suited for long-term use or use in high-pressure environments. Metal and composite materials exhibit superior fatigue resistance compared to flexible materials, maintaining their structural properties through thousands of pressure cycles. Flexible materials, while durable, experience ongoing stress-relaxation cycles that can lead to gradual degradation and potential failure points.

Safety Margins and Failure Modes

Hard shell construction provides predictable failure modes with significant safety margins. Metal structures typically exhibit gradual stress indicators before catastrophic failure, allowing for preventive maintenance and early detection of potential problems. The robust construction can accommodate emergency decompression procedures and withstand external impacts that might compromise flexible chambers.

Environmental Durability

While soft shell chambers compromise on the pressure that can be handled within the material, hard shell chambers maintain consistent performance across varying environmental conditions. Temperature fluctuations, humidity changes, and atmospheric pressure variations have minimal impact on rigid chamber performance, whereas flexible materials may experience dimensional changes that affect pressure delivery.

Maintenance and Longevity

Hardshell materials are selected for their ease of maintenance and long lifespan. The non-porous surfaces of metal and composite chambers resist contamination and allow for thorough cleaning and sterilization protocols essential in medical environments. Flexible materials, despite protective coatings, may develop micro-perforations or degradation that compromise sterility and pressure integrity over time.

Clinical Application Requirements

The reliability advantages of hard shell chambers become particularly important in clinical settings where treatment outcomes depend on precise HBOT pressure delivery and where patient safety cannot be compromised.

Soft chambers are considered lower quality than hard hyperbaric chambers and offer fewer benefits, reflecting the clinical preference for rigid chamber reliability in medical applications.

The material advantages of hard shell construction translate directly into enhanced patient safety, treatment consistency, and long-term operational reliability, making them the preferred choice for serious medical applications despite their higher initial cost and installation complexity.

Material Comparison: Hard Shell vs. Soft Shell HBOT Chambers: Reference Table

|

Feature / Material |

Hard Shell Chambers |

Soft Shell Chambers |

Rationale for Hard Shell Superiority |

|

Primary Structural Material |

Medical-grade stainless steel, aluminum, advanced composites (carbon fiber, reinforced polymers) |

Reinforced PVC, nylon, PET polyester, thermoplastic polyurethane (TPU) |

Rigid materials offer inherent structural integrity and high resistance to extreme pressures. |

|

Viewing Components |

Acrylic |

Not applicable (chambers are typically fully enclosed with no large viewing panels) |

Acrylic allows visual monitoring and can withstand significant pressure differentials without compromising integrity. |

|

Structural Integrity |

Self-supporting, rigid structure maintains shape under pressure |

Relies on continuous inflation to maintain shape |

Hard shell construction provides consistent internal dimensions and reliable pressure delivery, which is crucial for precise treatment protocols. |

|

Pressure Capabilities |

1.5 – 3.0 ATA (some specialized units higher) |

1.3 – 1.5 ATA |

Higher pressure capability is essential for therapeutic effects in many medical conditions and allows for greater oxygen dissolution in plasma. |

|

Fatigue Resistance |

Superior; maintains structural properties through thousands of pressure cycles. |

Lower experiences stress-relaxation cycles that can lead to gradual degradation and potential failure |

Metals and composites exhibit better long-term durability under repeated pressurization. |

|

Safety Margins |

Predictable failure modes with significant safety margins; exhibits gradual stress indicators |

Less predictable; potential for tears or micro-perforations |

Robust construction provides enhanced safety for critically ill patients and allows for preventive maintenance. |

|

Environmental Durability |

Consistent performance across varying environmental conditions (temperature, humidity) |

May experience dimensional changes affecting pressure delivery with environmental fluctuations |

Rigid materials are less susceptible to external environmental factors, ensuring consistent treatment. |

|

Maintenance & Longevity |

Non-porous, easy to clean/sterilize; long lifespan |

May develop micro-perforations or degradation over time; compromises sterility and pressure integrity |

Materials selected for hard shell chambers facilitate thorough cleaning and sterilization, which is essential for medical environments. |

|

Clinical Application |

Gold standard for acute, severe medical conditions requiring precise, high-pressure intervention |

Suitable for wellness applications; limited by lower pressure capabilities |

Hard shell chambers are preferred for reliability, precise pressure delivery, and enhanced patient safety in critical medical scenarios. |

What to Remember About Soft Shell Chambers

Soft-shell HBOT chambers are used in several specific contexts since they are not considered medical-grade devices:

Primary Applications

Soft-shell chambers are only FDA-approved for treating altitude sickness, which was their original intended application for divers and mountain climbers to use temporarily until they could get proper medical care.

Wellness and Recovery Uses

They are commonly used for short-term applications like recovery after intense physical activity and in wellness settings rather than medical facilities. These “mild hyperbaric oxygen therapy” (mHBOT) chambers are non-medical hyperbaric devices that work with oxygen of lower purity than medical oxygen.

Key Limitations

It’s important to understand that soft chambers are NOT medical devices, are not rated to acceptable engineering standards, and do not provide the same benefits as hard chambers. You won’t find mild or soft chambers in hospitals or reputable medical facilities because they are not recognized as medical devices for hyperbaric oxygen treatment.

So, while soft-shell chambers are useful in wellness or emergency altitude sickness treatment, they cannot substitute for medical-grade hard-shell chambers when treating serious medical conditions.

This article is intended for informational purposes only and should not be considered medical advice. Always consult with a qualified medical provider regarding HBOT treatment options.

If you have any questions please call our Hyperbaric Oxygen Clinic in Brooklyn NY, located at 1659 Ralph Ave. Our phone number is 718-255-9955